The advanced program involves development and dissemination

of the Vertical Shaft Brick Kiln (VSBK) technology, which was first developed

in China as energy efficient, environment-friendly and economically viable

means of producing high quality bricks.

Here are some of the shelter technologies besides VSBK, MCRT and CEB, which are discussed elsewhere in greater detail:

Concrete Block Technology (CBT)

Concrete Block Technology (CBT) (fig 1a) offers a speedier

alternative to conventional materials, since it is typically equivalent to 4.5

bricks.

They are compatible with other materials like fired bricks, CEBs and

dressed stone for composite wall construction, as shown below.

The most common sizes are 30 x 20 x 15 cm; its weight about

18-19 kg. The basic raw material is cement. Very little water is used. CBTs are

produced using a semi-mechanized stationary type machine. The other production

systems are:

§

Manual Moulds, which require hand tamping

§

Mobile Semi-Mechanized 'egg-laying' machine

§

Fully Mechanized system, which combines compression and vibration.

High quality machines provide optimum vibration in the mix,

so that the ratio of cement used can be reduced substantially, without

compromising on the strength of the blocks.

The blocks are cured for a minimum period of 14 days, before

use. On average, a skilled and 6-8 semi-skilled workers can make 600 - 800

blocks in 8 hours.

Ferrocement Roofing Channels (FRC)

The Ferrocement Roofing Channels (FRC) developed by DA uses

state-of-the-art design principles to manufacture reinforced shells, commonly

called channels, as shown below:

They have high density and are impervious to

penetration of water and provide high structural strength. FRCs can be used for

intermediate floor applications as well and offers a viable alternative to

conventional flat roofing systems.

FRCs have a uniform segmental profile of 2.5 cm thick and 83

cm wide. Maximum length of mechanically produced channels can be 6 meters.

Longer spans of roofs can be built with intermediate support. FRCs can be

safely transported after a curing period of 14 days. FRCs are prefabricated

elements. The mechanized system of production uses a vibrating table and

profiled steel shell moulds.

The production yard, as shown above, consists of a vibrating table positioned under a gantry system 6.5 meters in width. A production team consisting of 2 masons, 6 semi-skilled workers and a supervisor can produce upto 5 channels of 4.6 meters length each, in 8 hours of operation.

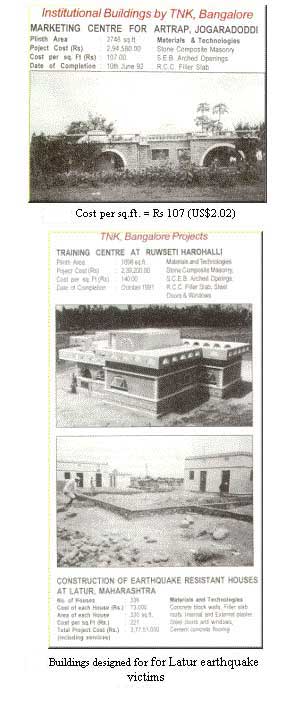

Buildings

The current cost of buildings made with Sankalp/TARA technology varies from Rs.150 to Rs. 250 per sq. ft. The buildings

shown below were designed for Latur earthquake victims, which cost Rs 221 per sq. ft.

Cost of buildings

The estimated cost of a bare single (10' x 12') dwelling

unit including a verandah space is about Rs. 20,000 (US$412), which means that the gross building cost is going to be

about Rs 170 per sq.ft (US$3.50 per sq.ft.) only. This compares very well with

current rates of between Rs 350 to 500 per sq.ft, using conventional building

materials. The basis of these cost estimates are given below:

A. COST OF ROOFING = Rs. 3,000 (US$62)

Assumptions:

a)

Cost of one tile is Rs. 6.

b)

Cost of understructure of bamboo and labour cost of making

understructure and tile laying is Rs. 10 per sq. ft. (US$0.20 per sq.ft.);

c)

Cost of construction of sloping roof using MCR tile and

understructure of bamboo is Rs. 25 per sq. ft. (US$0.52 per sq.ft.)

B. COST OF WALLS = Rs. 4,000 (US$83)

Assumptions:

a)

Cost of each CEB (Balram) brick is Rs. 1.20

b)

Cost of labour and mortar is Rs. 2,500.00

C. COST OF FOUNDATION = Rs. 5,000 (US$103)

Assumptions:

a)

Same as that for fired bricks.

D. COST OF DOOR AND 3 WINDOWS = Rs. 3,000 (US$62)

Assumptions:

a)

Cost of Door = Rs. 1,200.00

b)

Cost of Windows = Rs. 800.00

E. OVERHEAD CHARGES = Rs. 5,000 (US$103)

===========================================================

TOTAL COST

(A+B+C+D+E) = Rs. 20,000 (US$412)

===========================================================

Notes:

1.

Finishing operations (whether on interior or exterior walls,

or on floor) will cost extra.

2.

These are estimated costs. Precise cost estimates can be made

when we gather cost of local material and labour costs, in situ.