Preamble

Vertical Shaft Brick Kilns (VSBK) provides for cleaner brick production. Bricks remain one of the most important building materials in the country. Brick making is a traditional industry in India, generally confined to rural areas. Notably, the Indian brick industry, with more than 100,000 production units producing about 100 billion bricks annually, is the second largest brick producer in the world after that of China. The industry has an annual turnover of more than Rs.100 billion (US$ 2 billion) and, very importantly, it is one of the largest employment generating industries, employing millions of workers.

However, brick making is an energy intensive process as fuel costs account for almost 30% of the production cost.

Despite all initiatives to introduce alternative walling materials like compressed earth blocks, concrete / stonecrete blocks, and flyash bricks, it is envisaged that burnt clay bricks would still occupy the dominant position in the foreseeable decades.

Environmental impact

Current technologies for brick production such as clamps, downdraught kilns and Bull's Trench Kilns (BTK) consume large quantities of fuel such as coal, firewood and other biomass inputs.

The devastating effect of the pollution caused by huge amounts of emissions from the brick industry has attracted the attention of regulatory agencies, who have issued deadlines after which the polluting kilns have either to clean up or to close down permanently.

Advantages of VSBK technology

The advantages of VSBK technology are:

§

It represents a very high-energy efficient method of firing bricks resulting in an energy saving of 30 % compared to BTK and more than 50% compared to clamps. The fired quality is better than the quality of bricks fired in other traditional kilns such as clamps.

§

This kiln is very compact, requiring a small area of land. For the same production capacity, the land requirement is about 1/4th compared to BTK.

§

Easy to operate and does not require electricity to function.

§

The construction cost, though slightly higher than BTK, is still reasonably low - Rs.350,000 (US$7,000) for a production capacity of 5000 bricks per day.

§

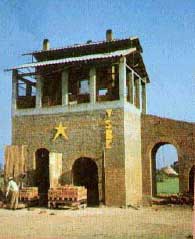

The kiln is not affected by variations in the weather. It can be operated during monsoons because unlike other traditional kilns, VSBK has a roof, which means protection from rain and year-round operations. Other brick kilns are able to operate only for 5 or 6 months in a year.

§

The kiln is highly suitable for use where fuel is incorporated into the brick. In several parts of the country, agricultural residue like rice husk or fuels like coal dust are mixed with clay before moulding. This allows use of inferior quality fuel and, in general, reduction in production cost. VSBK, because of its fast firing characteristics, is particularly suited for firing of brick containing internal fuel.

Modularity in construction and flexibility in production are important attributes of VSBK technology. Additional shafts of production capacity of 2,000 to 5,000 bricks per day can be easily added or operated according to the demand for bricks.